Last updated: 4/11/2007

OAQ Process Information Application PI-18 Mineral Processing {52559}

Start Your Free Trial $ 23.99What you get:

- Instant access to fillable Microsoft Word or PDF forms.

- Minimize the risk of using outdated forms and eliminate rejected fillings.

- Largest forms database in the USA with more than 80,000 federal, state and agency forms.

- Download, edit, auto-fill multiple forms at once in MS Word using our Forms Workflow Ribbon

- Trusted by 1,000s of Attorneys and Legal Professionals

Description

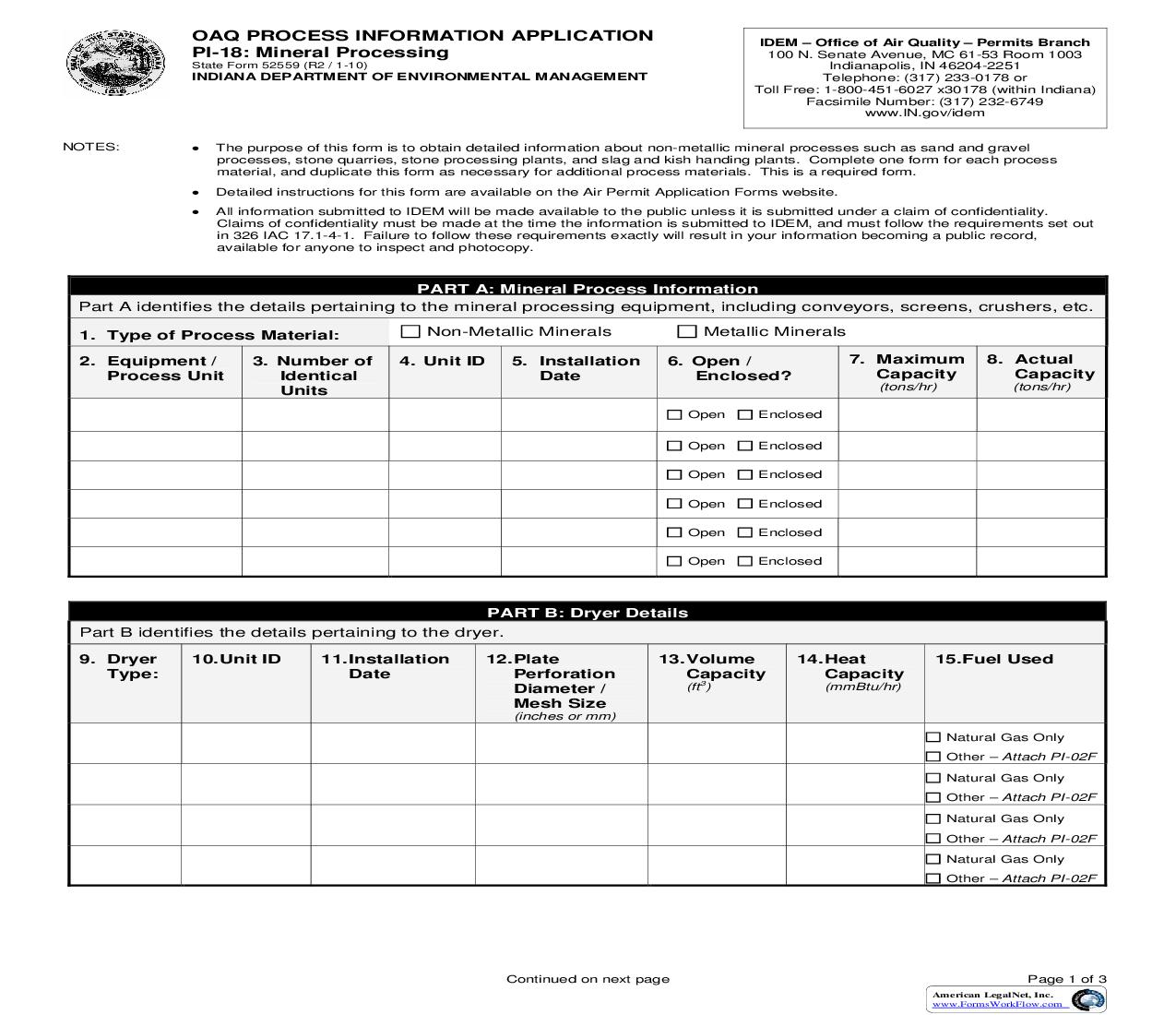

Indiana Department of Environmental Management Office of Air Quality Air Permit Application Page 1 of 4 PI-18 Instructions 5/2006 PROCESS INFORMATION: Mineral Processing INSTRUCTIONS Microsoft Word version of PI-18 Adobe PDF version of PI-18 The purpose of PI-18 (state form 52559) is to obtain detailed information about mineral processes, including non-metallic minerals and sand and gravel processes. Complete one form for each process (or group of identical processes). PI-18 is a required form for all air permit applications submitted to IDEM, OAQ. For the purposes of this form, the term "source" refers to the plant as a whole and NOT to the individual emissions units. If you do not provide the enough information to adequately describe the process, the application process may be stopped. If you have any questions, contact the Air Permit Reviewer of the Day (PROD) at (317) 233-0178 or 1-800-451-6027 extension 3-0178 (toll free call within Indiana). Part A: Mineral Processing Information Part A specifies the details of the mineral processing equipment including conveyors, screens, and crushers. 1. Type of Process Material: Specify whether the process material is metallic or non-metallic minerals. 2. Equipment / Process Unit: List each equipment or process unit. If there are multiple process units that are identical in nature, capacity, and use, you may use one row to summarize the data for the identical process units. 3. Number of Identical Units: Identical units must be of the same type, capacity, and installation date. If more than one identical unit, specify the number of units in the space provided. 4. Unit ID: Provide the identification number for each unit. The identification numbers listed on this form should correspond to the emissions unit identified on the Plant Layout and Process Flow diagrams. 5. Installation Date: Provide the date on which the process unit was installed. If the exact date is not known, provide the month and year of the installation. If the unit has not yet been installed, provide the anticipated installation date. If the unit has been modified since the original installation, include the most recent modification date. 6. Open / Enclosed: Specify whether each process unit is open to the atmosphere or enclosed in a building. 7. Maximum Capacity: Provide the maximum processing capacity of each process unit in tons per hour (tons/hr). 8. Actual Capacity: Provide the average actual processing capacity of each process unit in tons per hour (tons/hr). Part B: Dryer Details Part B specifies the details of the process dryers. 9. Dryer Type: List each type of dryer used in the process. If there are multiple dryers that are identical in nature, capacity, and use, you may use one row to summarize the data for the identical units. 10. Unit ID: Provide the identification number for each unit. The identification numbers listed on this form should correspond to the emissions unit identified on the Plant Layout and Process Flow diagrams. American LegalNet, Inc. www.FormsWorkflow.com Indiana Department of Environmental Management Office of Air Quality Air Permit Application Page 2 of 4 PI-18 Instructions 5/2006 11. Installation Date: Provide the date on which each dryer was installed. If the exact date is not known, provide the month and year of the installation. If the unit has not yet been installed, provide the anticipated installation date. If the unit has been modified since the original installation, include the most recent modification date. 12. Plate Perforation Diameter / Mesh Size: Provide the plate perforation diameter or mesh size of each dryer in inches (in) or millimeters (mm). Specify which units of measure were used. 13. Volume Capacity: Provide the volumetric capacity of each dryer in cubic feet (ft3). 14. Heat Capacity: Provide the heat capacity of each dryer in million British thermal units per hour (MMBtu/hr). 15. Fuel Used: If applicable, specify whether natural gas is used as the only process fuel. If a fuel other than natural gas is used, include the PI-02F form identifying all fuels used for the process. Complete the applicable PI-02 forms for the combustion process. Part C: Storage and Handling of Materials Part C specifies the details pertaining to aggregate storage and handling. 16. Material Size & Specification: List each type of material stored or handled as part of the process. Include the grain size of the material as well as any other pertinent specifications. 17. Type of Storage: Describe how the material is stored for the process. 18. Storage Capacity: Provide the maximum annual storage capacity for each material in metric tons. 19. Unit ID: Provide the identification number for each unit. The identification numbers listed on this form should correspond to the emissions unit identified on the Plant Layout and Process Flow diagrams. 20. Installation Date: Provide the date on which each dryer was installed. If the exact date is not known, provide the month and year of the installation. If the unit has not yet been installed, provide the anticipated installation date. If the unit has been modified since the original installation, include the most recent modification date. 21. Storage Open or Totally Enclosed / Covered: Specify whether each storage area is open to the atmosphere, enclosed in a building or storage unit, or covered in some fashion. Part D: Emission Factors Part D identifies the emission factors used to calculate air emissions from this process. 22. Process Unit: Identify the process and include the identification number for the unit, if applicable. 23. Air Pollutant: For each process identified, list each air pollutant emitted to the atmosphere during normal operation. If there are multiple pollutants for an process, use a new row for each pollutant. 24. Emission Factor: Provide the relevant emission factor including the appropriate units (e.g., lb/units, lbs/ton, lbs/gal, lbs/cf, etc.). American LegalNet, Inc. www.FormsWorkflow.com Indiana Department of Environmental Management Office of Air Quality Air Permit Application Page 3 of 4 PI-18 Instructions 5/2006 25. Source of Emission Factor: Provide the source of the emission factors. Common sources include AP-42, stack test data, engineering analysis. The United States Environmental Protection Agency (U.S. EPA) has developed a Clearinghouse for Inventories & Emission Factors containing AP-42 and other emission factors. Appendix A of AP-42 lists several common conversion

Related forms

-

OAQ Process Information Application PI-17 Blasting Operations

OAQ Process Information Application PI-17 Blasting Operations

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ Process Information Application PI-05 Brick And Clay Products

OAQ Process Information Application PI-05 Brick And Clay Products

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ Process Information Application PI-02B Combustion Boilers Process Heaters And Furnaces

OAQ Process Information Application PI-02B Combustion Boilers Process Heaters And Furnaces

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ Process Information Application PI-02G Combustion Emission Factors

OAQ Process Information Application PI-02G Combustion Emission Factors

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ Process Information Application PI-02H Combustion Federal Rule Applicability

OAQ Process Information Application PI-02H Combustion Federal Rule Applicability

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ Process Information Application PI-02F Combustion Fuel Use

OAQ Process Information Application PI-02F Combustion Fuel Use

Indiana/Statewide/Department Of Enviromental Management/Air/ -

General Source Data Application GSD-14 Owners And Occupants Notified

General Source Data Application GSD-14 Owners And Occupants Notified

Indiana/Statewide/Department Of Enviromental Management/Air/ -

General Source Data GSD-15 Government Officials Notified

General Source Data GSD-15 Government Officials Notified

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ General Source Data Application GSD-02 Plant Layout Diagram

OAQ General Source Data Application GSD-02 Plant Layout Diagram

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ General Source Data Application GSD-01 Basic Source level Information

OAQ General Source Data Application GSD-01 Basic Source level Information

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ Process Information Application PI-02D Combustion Incinerators And Combustors

OAQ Process Information Application PI-02D Combustion Incinerators And Combustors

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ Process Information Application PI-02E Combustion Kilns

OAQ Process Information Application PI-02E Combustion Kilns

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ Process Information Application PI-02C Combustion Turbines Reciprocating Internal Engines

OAQ Process Information Application PI-02C Combustion Turbines Reciprocating Internal Engines

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ Process Information Application PI-02A Combustion Unit Summary

OAQ Process Information Application PI-02A Combustion Unit Summary

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ Process Information Application PI-08 Concrete Batchers

OAQ Process Information Application PI-08 Concrete Batchers

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ Process Information Application PI-09 Degreasing Operations

OAQ Process Information Application PI-09 Degreasing Operations

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ Process Information Application PI-10 Dry Cleaning Operations

OAQ Process Information Application PI-10 Dry Cleaning Operations

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ Process Information Application PI-06 Electroplating

OAQ Process Information Application PI-06 Electroplating

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ Process Information Application PI-11 Foundry Smelting And Die Cast Operations

OAQ Process Information Application PI-11 Foundry Smelting And Die Cast Operations

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ Process Information Application PI-12 Grain Elevators

OAQ Process Information Application PI-12 Grain Elevators

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ Process Information Application PI-04 Hot Or Cold Mix Asphalt Plants

OAQ Process Information Application PI-04 Hot Or Cold Mix Asphalt Plants

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ Process Information Application PI-13 Lime Manufacturing

OAQ Process Information Application PI-13 Lime Manufacturing

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ Process Information Application PI-18 Mineral Processing

OAQ Process Information Application PI-18 Mineral Processing

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ Process Information Application PI-01 Miscellaneous Processes

OAQ Process Information Application PI-01 Miscellaneous Processes

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ Process Information Application PI-15 Portland Cement Manufacturing

OAQ Process Information Application PI-15 Portland Cement Manufacturing

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ Process Information Application PI-16 Reinforced Plastics And Composites

OAQ Process Information Application PI-16 Reinforced Plastics And Composites

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ Process Information Application PI-21 Site Remediation

OAQ Process Information Application PI-21 Site Remediation

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ Process Information Application PI-03 Storage And Handling Of Bulk Material

OAQ Process Information Application PI-03 Storage And Handling Of Bulk Material

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ Process Information Application PI-19 Surface Coating And Printing Operations

OAQ Process Information Application PI-19 Surface Coating And Printing Operations

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ Process Information Application PI-14 Volatile Organic Liquid Compound Storage

OAQ Process Information Application PI-14 Volatile Organic Liquid Compound Storage

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ Process Information Application PI-07 Welding And Cutting Of Metal

OAQ Process Information Application PI-07 Welding And Cutting Of Metal

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ Process Information Application PI-20 Woodworking And Plastic Machining

OAQ Process Information Application PI-20 Woodworking And Plastic Machining

Indiana/Statewide/Department Of Enviromental Management/Air/ -

AEF-01 Alternate Emission Factor Request

AEF-01 Alternate Emission Factor Request

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ General Source Data Application GSD-03 Process Flow Diagram

OAQ General Source Data Application GSD-03 Process Flow Diagram

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ General Source Data Application GSD-04 Stack Vent Information

OAQ General Source Data Application GSD-04 Stack Vent Information

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ General Source Data Application GSD-05 Emissions Unit Information

OAQ General Source Data Application GSD-05 Emissions Unit Information

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ General Source Data Application GSD-06 Particulate Emissions Summary

OAQ General Source Data Application GSD-06 Particulate Emissions Summary

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ General Source Data Application GSD-07 Criteria Pollutant Emissions Summary

OAQ General Source Data Application GSD-07 Criteria Pollutant Emissions Summary

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ General Source Data Application GSD-08 Hazardous Air Pollutant Emissions Summary

OAQ General Source Data Application GSD-08 Hazardous Air Pollutant Emissions Summary

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ General Source Data Application GSD-09 Summary Of Additional Information

OAQ General Source Data Application GSD-09 Summary Of Additional Information

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ General Source Data Application GSD-10 Insignificant Activities

OAQ General Source Data Application GSD-10 Insignificant Activities

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ General Source Data Application GSD-11 Alternative Operating Scenario Summary

OAQ General Source Data Application GSD-11 Alternative Operating Scenario Summary

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ General Source Data Application GSD-12 Affidavit Of Nonapplicability

OAQ General Source Data Application GSD-12 Affidavit Of Nonapplicability

Indiana/Statewide/Department Of Enviromental Management/Air/ -

Air Permit Application Cover Sheet

Air Permit Application Cover Sheet

Indiana/Statewide/Department Of Enviromental Management/Air/ -

General Source Data Application GSD-13 Affidavit Of Applicability

General Source Data Application GSD-13 Affidavit Of Applicability

Indiana/Statewide/Department Of Enviromental Management/Air/ -

Air Permit Application Form Checklist

Air Permit Application Form Checklist

Indiana/Statewide/Department Of Enviromental Management/Air/ -

PAL-02 Revised Plantwide Applicability Limit

PAL-02 Revised Plantwide Applicability Limit

Indiana/Statewide/Department Of Enviromental Management/Air/ -

PAL-03 Plantwide Applicability Limit Renewal

PAL-03 Plantwide Applicability Limit Renewal

Indiana/Statewide/Department Of Enviromental Management/Air/ -

PAL-04 Request For Termination Of Plantwide Applicability Limit

PAL-04 Request For Termination Of Plantwide Applicability Limit

Indiana/Statewide/Department Of Enviromental Management/Air/ -

PAL-01 Actuals Plantwide Applicability Limit

PAL-01 Actuals Plantwide Applicability Limit

Indiana/Statewide/Department Of Enviromental Management/Air/ -

Application For Individual Asbestos License

Application For Individual Asbestos License

Indiana/Statewide/Department Of Enviromental Management/Air/ -

Application For Individual Lead License

Application For Individual Lead License

Indiana/Statewide/Department Of Enviromental Management/Air/ -

Application For Lead Based Paint Training Course Provider Approval

Application For Lead Based Paint Training Course Provider Approval

Indiana/Statewide/Department Of Enviromental Management/Air/ -

Application For Lead Contractor

Application For Lead Contractor

Indiana/Statewide/Department Of Enviromental Management/Air/ -

Inital Notification Report Under Regulation 40 CFR Part 63 Subpart DDDDD

Inital Notification Report Under Regulation 40 CFR Part 63 Subpart DDDDD

Indiana/Statewide/Department Of Enviromental Management/Air/ -

Notification Of Demolition And Renovation Operations

Notification Of Demolition And Renovation Operations

Indiana/Statewide/Department Of Enviromental Management/Air/ -

Notification Of Lead Abatement Activities

Notification Of Lead Abatement Activities

Indiana/Statewide/Department Of Enviromental Management/Air/ -

Registration Form For Lead Based Paint Third Party Examinations

Registration Form For Lead Based Paint Third Party Examinations

Indiana/Statewide/Department Of Enviromental Management/Air/ -

Request For Use Of An Air Curtain Open Pit Destructor

Request For Use Of An Air Curtain Open Pit Destructor

Indiana/Statewide/Department Of Enviromental Management/Air/ -

Request For Variance Form 326 IAC 4-1 Fire Training

Request For Variance Form 326 IAC 4-1 Fire Training

Indiana/Statewide/Department Of Enviromental Management/Air/ -

Request For Variance Form 326 IAC 4-1 Motor Vehicle Fire Training

Request For Variance Form 326 IAC 4-1 Motor Vehicle Fire Training

Indiana/Statewide/Department Of Enviromental Management/Air/ -

Request For Variance Form 326 IAC 4-1 Prescribed Vegetation Burn

Request For Variance Form 326 IAC 4-1 Prescribed Vegetation Burn

Indiana/Statewide/Department Of Enviromental Management/Air/ -

Request For Variance Form 326 IAC 4-1 Tree Waste Or Clean Wood Waste

Request For Variance Form 326 IAC 4-1 Tree Waste Or Clean Wood Waste

Indiana/Statewide/Department Of Enviromental Management/Air/ -

Application For Duplicate Lead License

Application For Duplicate Lead License

Indiana/Statewide/Department Of Enviromental Management/Air/ -

Application Checksheet For Asbestos Contractor

Application Checksheet For Asbestos Contractor

Indiana/Statewide/Department Of Enviromental Management/Air/ -

Application For Asbestos Contractor License

Application For Asbestos Contractor License

Indiana/Statewide/Department Of Enviromental Management/Air/ -

Application For Asbestos Training Course Provider Approval

Application For Asbestos Training Course Provider Approval

Indiana/Statewide/Department Of Enviromental Management/Air/ -

Application For Duplicate Asbestos License

Application For Duplicate Asbestos License

Indiana/Statewide/Department Of Enviromental Management/Air/ -

MACT-01 Pre Construction Review

MACT-01 Pre Construction Review

Indiana/Statewide/Department Of Enviromental Management/Air/ -

AES-03 Stack Information

AES-03 Stack Information

Indiana/Statewide/Department Of Enviromental Management/Air/ -

AES-04 Abatement Equipment

AES-04 Abatement Equipment

Indiana/Statewide/Department Of Enviromental Management/Air/ -

AES-05 Group Process Emissions Information

AES-05 Group Process Emissions Information

Indiana/Statewide/Department Of Enviromental Management/Air/ -

AES-06 Voluntary Hazardous Air Pollutant Reporting

AES-06 Voluntary Hazardous Air Pollutant Reporting

Indiana/Statewide/Department Of Enviromental Management/Air/ -

AES-01 Air Emission Statement Certification

AES-01 Air Emission Statement Certification

Indiana/Statewide/Department Of Enviromental Management/Air/ -

AES-02 Facility General Information

AES-02 Facility General Information

Indiana/Statewide/Department Of Enviromental Management/Air/ -

CD-02 Compliance Plan Requirements Per Applicable Requirement

CD-02 Compliance Plan Requirements Per Applicable Requirement

Indiana/Statewide/Department Of Enviromental Management/Air/ -

CD-03 Compliance Plan Requirements Per Emissions Unit

CD-03 Compliance Plan Requirements Per Emissions Unit

Indiana/Statewide/Department Of Enviromental Management/Air/ -

CD-04 Compliance Schedule And Certification

CD-04 Compliance Schedule And Certification

Indiana/Statewide/Department Of Enviromental Management/Air/ -

CD-01 Emissions Unit Compliance Status

CD-01 Emissions Unit Compliance Status

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ Control Equpiment Application CE-05 Particulate Control Wet Collector Scrubber Absorption

OAQ Control Equpiment Application CE-05 Particulate Control Wet Collector Scrubber Absorption

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ Control Equpiment Application CE-06 Organics Flare Oxidizer Incinerator

OAQ Control Equpiment Application CE-06 Organics Flare Oxidizer Incinerator

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ Control Equpiment Application CE-07 Organics Adsorber

OAQ Control Equpiment Application CE-07 Organics Adsorber

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ Control Equpiment Application CE-08 Organics Condenser

OAQ Control Equpiment Application CE-08 Organics Condenser

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ Control Equpiment Application CE-09 Nitrogen Oxides Reduction Technology

OAQ Control Equpiment Application CE-09 Nitrogen Oxides Reduction Technology

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ Control Equpiment Application CE-10 Miscellaneous Control Equipment

OAQ Control Equpiment Application CE-10 Miscellaneous Control Equipment

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ Control Equpiment Application CE-01 Control Equipment Summary

OAQ Control Equpiment Application CE-01 Control Equipment Summary

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ Control Equpiment Application CE-02 Particulate Control Baghouse Fabric Filter

OAQ Control Equpiment Application CE-02 Particulate Control Baghouse Fabric Filter

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ Control Equpiment Application CE-03 Particulate Control Cyclone

OAQ Control Equpiment Application CE-03 Particulate Control Cyclone

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ Control Equpiment Application CE-04 Particulate Control Electrostatic Precipitator

OAQ Control Equpiment Application CE-04 Particulate Control Electrostatic Precipitator

Indiana/Statewide/Department Of Enviromental Management/Air/ -

EC-03 Emission Credit Registry Use Of Emission Credits

EC-03 Emission Credit Registry Use Of Emission Credits

Indiana/Statewide/Department Of Enviromental Management/Air/ -

EC-04 Emission Credit Registry Emission Credits Request

EC-04 Emission Credit Registry Emission Credits Request

Indiana/Statewide/Department Of Enviromental Management/Air/ -

EC-01 Emission Credit Registry Generation Of Emission Credits

EC-01 Emission Credit Registry Generation Of Emission Credits

Indiana/Statewide/Department Of Enviromental Management/Air/ -

EC-02 Emission Credit Registry Transfer Of Emission Credits

EC-02 Emission Credit Registry Transfer Of Emission Credits

Indiana/Statewide/Department Of Enviromental Management/Air/ -

Identification Of Potentially Affected Persons

Identification Of Potentially Affected Persons

Indiana/Statewide/Department Of Enviromental Management/Air/ -

BACT 01A Background Search Existing BACT Determinations

BACT 01A Background Search Existing BACT Determinations

Indiana/Statewide/Department Of Enviromental Management/Air/ -

BACT 01B Cost Economic Impact Analysis

BACT 01B Cost Economic Impact Analysis

Indiana/Statewide/Department Of Enviromental Management/Air/ -

BACT 02 Summary Of Best Available Control Technology

BACT 02 Summary Of Best Available Control Technology

Indiana/Statewide/Department Of Enviromental Management/Air/ -

BACT 01 Analysis Of Best Available Control Technology

BACT 01 Analysis Of Best Available Control Technology

Indiana/Statewide/Department Of Enviromental Management/Air/ -

OAQ Permit Renewal Application Air Permit Renewal Checklist

OAQ Permit Renewal Application Air Permit Renewal Checklist

Indiana/Statewide/Department Of Enviromental Management/Air/ -

Application Checksheet For Lead Contractor

Application Checksheet For Lead Contractor

Indiana/Statewide/Department Of Enviromental Management/Air/

Form Preview

Contact Us

Success: Your message was sent.

Thank you!